Industrial waste management depends on a vast network of roll-off containers, open-top bins, commercial dumpsters, compactors, recycling containers, and regulated waste units. Yet even in 2025, many industrial waste haulers still struggle with a basic operational question:

Where are all of our containers right now?

As fuel costs rise, labor remains tight, and customers demand greater accountability, leading operators are turning to roll-off container tracking, waste bin GPS trackers, and dumpster tracking GPS systems. These are not consumer devices. They are industrial telematics platforms engineered for harsh environments across construction sites, manufacturing facilities, landfills, ports, refineries, and energy operations.

This guide explores the universal pain points that affect nearly every industrial waste operation, followed by the segment-specific challenges that make container tracking essential in today’s market.

Universal Pain Points GPS Tracking Solves Across Industrial Waste Operations

Container Theft, Misplacement, and Unauthorized Use

Roll-off containers and industrial dumpsters routinely move between job sites, subcontractors, and facilities without documentation. According to the National Equipment Register (NER), construction and industrial job-site asset theft costs between $300 million and $1 billion annually (NER Annual Theft Report).

Why does this happen so often?

Because containers are mobile, valuable, and rarely monitored once dropped.

With roll-off container tracking, operations teams gain continuous visibility. Real-time location data shows exactly where containers are at any moment. Geofencing alerts flag when containers leave approved sites. Over time, movement history exposes unauthorized subcontractor use and dramatically improves recovery of misplaced or stolen assets.

Idle Containers and Slow Turnaround Times

Even strong operations are often surprised by how many containers sit idle. The Solid Waste Association of North America (SWANA) estimates that inefficient routing and unused assets result in 15–20 percent lost productivity across hauling operations (SWANA Applied Research Foundation studies).

Why does idle inventory matter?

Because every empty roll-off represents revenue sitting still instead of moving.

GPS visibility identifies underutilized containers, shortens turnaround cycles, improves forecasting, and reduces the need to purchase excess inventory. Idle time becomes a measurable operational lever instead of hidden loss.

Unverified Drop-Offs, Pickups, and Rental Cycles

Industrial customers frequently dispute whether containers arrived or were removed on time. SWANA and Waste Today estimate that billing disputes consume 3–5 percent of annual hauler revenue (Waste Today Market Analysis; SWANA Operations Research).

A common customer question is:

“Can you prove when the container arrived and when it was picked up?”

Dumpster tracking GPS answers automatically. Each delivery and pickup is timestamped, dwell time is recorded without driver input, and rental periods are documented with verifiable data. Conversations shift from disputes to proof.

Route Inefficiency and Wasted Labor Hours

The U.S. Environmental Protection Agency (EPA) reports that 60–80 percent of total waste-handling costs are tied to collection and transportation (EPA Municipal Solid Waste Facts & Figures). On large industrial sites, drivers can spend 30–90 minutes per stop searching for containers that are not where dispatch expected them to be.

Why is route efficiency so difficult in industrial waste operations?

Because job sites evolve daily, containers are constantly repositioned, and location data becomes outdated almost immediately.

Waste route optimization GPS reduces search time by giving drivers precise container locations before they arrive, improving fuel efficiency, service consistency, and driver productivity.

Limited Visibility for Dispatch and Operations Teams

Many industrial waste operations still rely on spreadsheets, whiteboards, phone calls, and driver memory to manage hundreds or thousands of containers.

Is GPS tracking accurate enough for industrial environments?

Yes. Modern waste management telematics platforms are engineered for vibration, moisture, temperature extremes, and multi-year deployment cycles.

With GPS tracking, operations teams gain a true single source of truth: real-time container locations, balanced inventory across regions, improved forecasting, and faster response to urgent service requests.

Rising Customer Expectations and Compliance Pressure

Industrial customers increasingly expect transparency, digital documentation, and verified service. A McKinsey & Company study found that 70 percent of B2B buyers rank reliability and transparency as top decision factors (McKinsey B2B Decision-Making Research).

GPS tracking creates consistent digital records of service activity, strengthens audit trails, and improves retention of enterprise customers.

Segment-Specific Pain Points in Industrial Waste Management

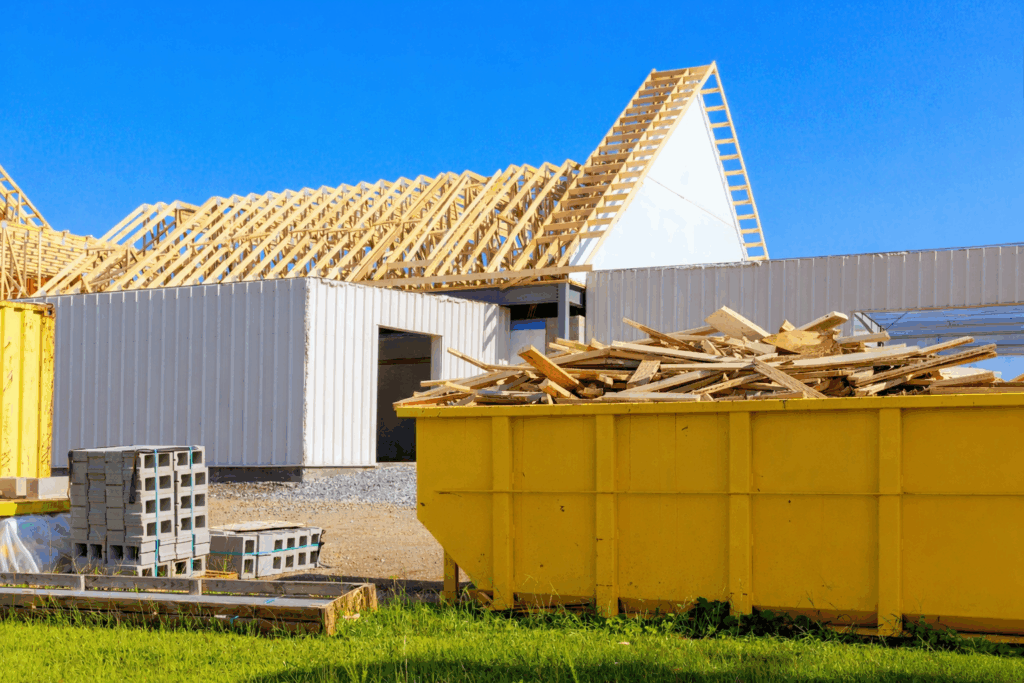

Roll-Off Containers for Construction, Industrial, and Demolition

Roll-offs move constantly across job sites, often handled by multiple subcontractors. Containers are relocated without notice, blocked by equipment, buried under debris, and shuffled between locations with little documentation.

How do haulers track roll-offs when crews move them constantly?

GPS tracking with geofencing provides visibility without relying on drivers or site personnel.

Commercial & Industrial Dumpsters and Compactors

Large facilities frequently reposition dumpsters and compactors to accommodate shifting workflows. Drivers arrive to find containers relocated, locked, or hidden behind structures. Service disputes and wasted labor follow.

Dumpster tracking GPS restores certainty by showing exactly where containers are and verifying when service occurs.

Recycling Containers and Sustainability Programs

Recycling operations rely on high-value containers that rotate rapidly. Without visibility, containers disappear, cycle times stretch, and ESG reporting becomes difficult.

GPS tracking creates auditable movement history, improves inventory control, and strengthens sustainability documentation.

Hazardous, Medical, and Regulated Waste Containers

Hazardous waste handling is governed by strict regulations. Missing containers create serious liability and compliance risk.

GPS tracking creates a digital chain-of-custody record that improves accountability and reduces regulatory exposure.

Large Events, Stadiums, and Temporary Industrial Deployments

Temporary deployments use industrial roll-offs and dumpsters spread across large areas. Overflow, lost assets, and excessive labor are common.

Real-time container visibility allows crews to service only what is needed and recover assets efficiently after teardown.

Why Industrial Waste Operations Are Adopting GPS at Scale

Haulers using waste management telematics report:

- 10–25 percent reduction in idle containers (Waste Today Market Report)

- Up to 30 percent fuel savings from route optimization (EPA SmartWay Program)

- Significant reductions in lost or stolen containers

- Faster turnaround and higher revenue per asset

- Improved customer retention through service transparency

For mid-size and large haulers, these gains translate into hundreds of thousands to millions of dollars in annual operational improvement.

Industrial Waste Requires Industrial-Grade Visibility

Industrial waste operations are asset-heavy and fast-moving. Containers are constantly in motion, and without GPS, they disappear into costly blind spots.

Roll-off container tracking, dumpster tracking GPS, and waste bin GPS tracker systems turn static containers into traceable, verifiable, revenue-producing assets. For industrial waste haulers focused on growth, efficiency, and competitive advantage, container tracking is no longer optional.

Is GPS tracking becoming the industry standard?

Yes. As margins tighten and expectations rise, industrial waste container tracking is quickly becoming the operational baseline.

If your operation is still managing roll-offs and industrial waste containers with spreadsheets, phone calls, and driver memory, it’s time to upgrade to full asset visibility.

Modern GPS container tracking gives you the control, proof, and performance today’s waste operations need to stay competitive.

Get a quote today to see what full container visibility could look like for your operation.

Publisher: Source link