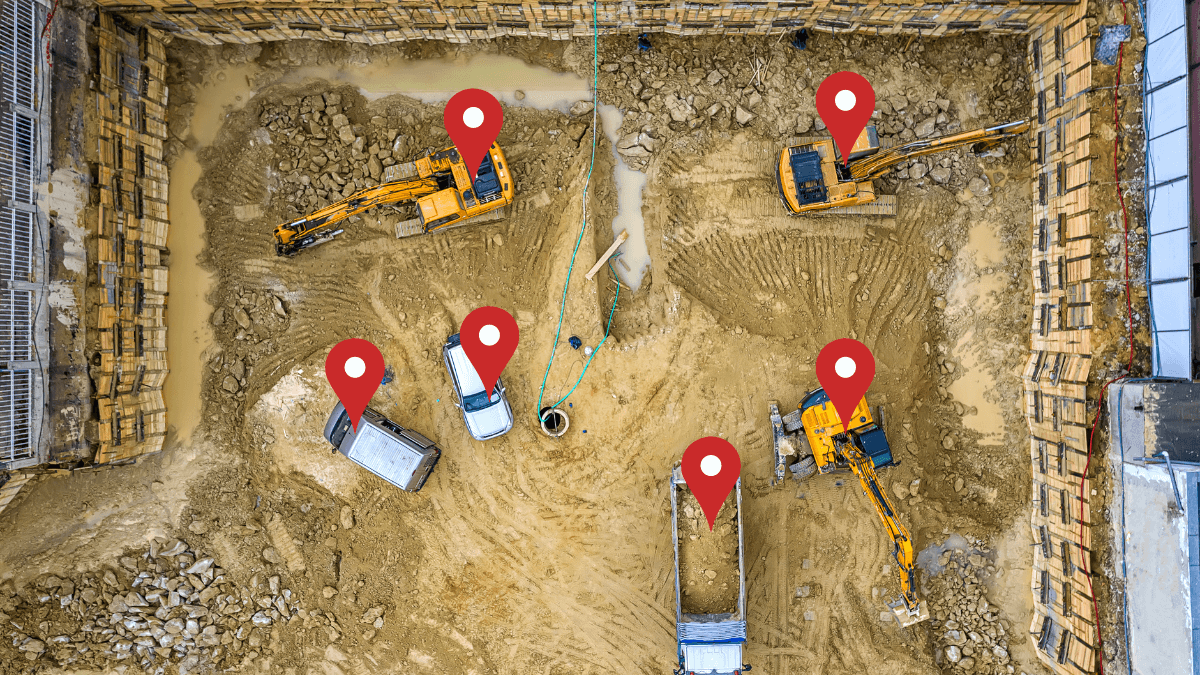

Implementing asset tagging systems can present several challenges, such as harsh environmental conditions that can damage tags and the complexity of tracking large fleets. For outdoor settings, traditional tags may not endure weather elements, leading to data inaccuracies. Additionally, ensuring consistent tag readings across different equipment types can be a logistical hurdle.

Metal asset tags for equipment form quite a robust solution for the toughest of environments since the tags themselves are durable and resistant to damage. An overall staff training program can ensure proper usage and maintenance of the tagging system. Regular audits and updates can address and mitigate inconsistencies in the asset tracking system.

Publisher: Source link